Choosing between VG10 and 440C steel depends on your needs. Here's the quick takeaway:

- VG10 Steel: Offers excellent sharpness, edge retention, and corrosion resistance, making it ideal for high-volume salons and advanced cutting techniques. It's durable and requires less maintenance but comes at a higher cost.

- 440C Steel: A budget-friendly option with good sharpness and durability. Easier to maintain and sharpen, it's suitable for everyday use but doesn't match VG10's edge retention or precision.

Quick Comparison

| Feature | VG10 Steel | 440C Steel |

|---|---|---|

| Sharpness | Superior | Good |

| Edge Retention | Excellent | Good |

| Corrosion Resistance | Superior | Good |

| Durability | High | Above Average |

| Maintenance | Minimal | Moderate |

| Cost | Higher | Lower |

If you need long-lasting precision and can invest more, go for VG10. For reliable performance at a lower price, 440C is a solid choice.

Features of VG10 Steel

VG10 Steel Composition and Hardness

VG10 steel stands out thanks to its 1% carbon content and the addition of vanadium and titanium. These elements contribute to its impressive Rockwell Hardness of 59-61 HRC, which means it holds an edge well and lasts longer [1][2]. Often, VG10 is crafted with a laminated structure - this combines a tough, corrosion-resistant outer layer with a hard inner core for extra strength [5].

VG10 Steel Performance

The high hardness of VG10 ensures it keeps a sharp edge for longer periods, making it a favorite for precision work. Its resistance to rust and ability to maintain sharpness make it an excellent choice for detailed, intricate cutting tasks [4][3]. Plus, it doesn’t need sharpening as often, which is a big time-saver for professionals. To maintain its performance, it’s important to sharpen regularly and avoid letting it stay wet for too long.

VG10 steel is particularly suited for jobs requiring accuracy and finesse. For instance, Shihan Shears uses VG10 to create tools that deliver precise, reliable results for professionals who depend on long-lasting performance.

Although VG10 excels in sharpness and durability, 440C steel brings its own set of benefits worth considering.

Features of 440C Steel

440C Steel Composition and Hardness

440C steel is known for its high carbon content (0.95-1.20%) and chromium levels (16-18%), which give it a solid mix of hardness, corrosion resistance, and wear resistance - qualities that make it a popular choice for professional-grade shears [4]. With a Rockwell Hardness rating of 58-59 HRC [3], it stands out as the top-performing grade in the 440 series, outperforming both 440A and 440B in durability and strength [3].

440C Steel Performance

When put to the test, 440C steel delivers dependable cutting performance at a cost-effective price, making it a go-to option for professionals who need quality tools without the higher expense of VG10 steel [4]. While it holds an edge well, its sharpness and edge retention don't quite match the higher standards set by VG10 steel [3]. Still, for stylists working with a high number of clients, 440C shears offer reliability and are easy to maintain, ensuring steady results.

To keep these shears in top condition, regular cleaning, drying, and professional sharpening are essential. With proper care, 440C steel maintains its strength and durability, making it a practical choice for daily use in busy salon settings where consistent performance is critical [4][3].

Although 440C strikes a good balance between performance and cost, comparing it directly with VG10 steel can help professionals choose the best option for their needs.

VG10 vs. 440C: Comparing Key Features

Sharpness and Edge Retention Comparison

VG10 stands out for its high carbon and cobalt content, giving it an edge - literally - when it comes to sharpness and edge retention. It holds its cutting edge longer than 440C [3].

| Feature | VG10 Steel | 440C Steel |

|---|---|---|

| Initial Sharpness | Superior | Good |

| Edge Retention | Excellent | Good |

| Rockwell Hardness | 59-61 HRC | 58-59 HRC |

While sharpness is crucial, durability and corrosion resistance are equally important for ensuring long-term performance.

Durability and Corrosion Resistance Comparison

VG10’s alloy composition, including vanadium and cobalt, boosts its durability, wear resistance, and protection against corrosion. This makes it more robust compared to 440C [2]. Both steels are durable, but VG10’s enhanced properties make it a stronger contender for demanding use [1].

| Characteristic | VG10 Steel | 440C Steel |

|---|---|---|

| Wear Resistance | Advanced | Good |

| Corrosion Protection | Superior | Good |

| Overall Durability | Excellent | Above Average |

| Maintenance Requirements | Minimal | Moderate |

Deciding between these steels often comes down to matching their features to specific professional requirements.

Which Steel is Better for Professionals?

The choice between VG10 and 440C depends on the demands of the user [4]. VG10 is ideal for high-volume salon work, where consistent performance and low maintenance are priorities. Its excellent edge retention is a major advantage for precision cutting and advanced styling [3].

| Professional Need | Recommended Steel | Reasoning |

|---|---|---|

| High-Volume Salon | VG10 | Better edge retention, less upkeep |

| Advanced Cutting Techniques | VG10 | Greater precision and control |

| Budget-Conscious Practice | 440C | Good quality at a lower price |

| Regular Use | 440C | Reliable with proper care |

"For peak performance and longevity, VG10 steel is generally recommended, while 440C steel is suitable for less demanding use" [4][2].

For stylists handling high workloads or intricate techniques, VG10 is worth the extra investment. On the other hand, 440C offers solid performance at a more affordable price. This comparison helps professionals weigh cost, performance, and upkeep to make the best choice for their needs.

sbb-itb-a50b05d

How to Choose the Right Steel for Your Shears

Factors to Consider for Stylists and Barbers

Choosing between VG10 and 440C steel shears depends on your work style and preferences. VG10 is ideal for high-volume, precision tasks and comes with a higher price tag. On the other hand, 440C is a more budget-friendly option for professionals with moderate workloads.

Your cutting technique also plays a role. VG10's hardness makes it great for advanced methods like slide and point cutting [1], while 440C is dependable for standard techniques. VG10 shears need less frequent sharpening, whereas 440C requires more upkeep.

Here are some key points to think about:

| Factor | What to Consider |

|---|---|

| Cutting Techniques | Advanced precision vs. standard work |

| Maintenance | Low-maintenance vs. frequent sharpening |

| Investment | Durability vs. affordability |

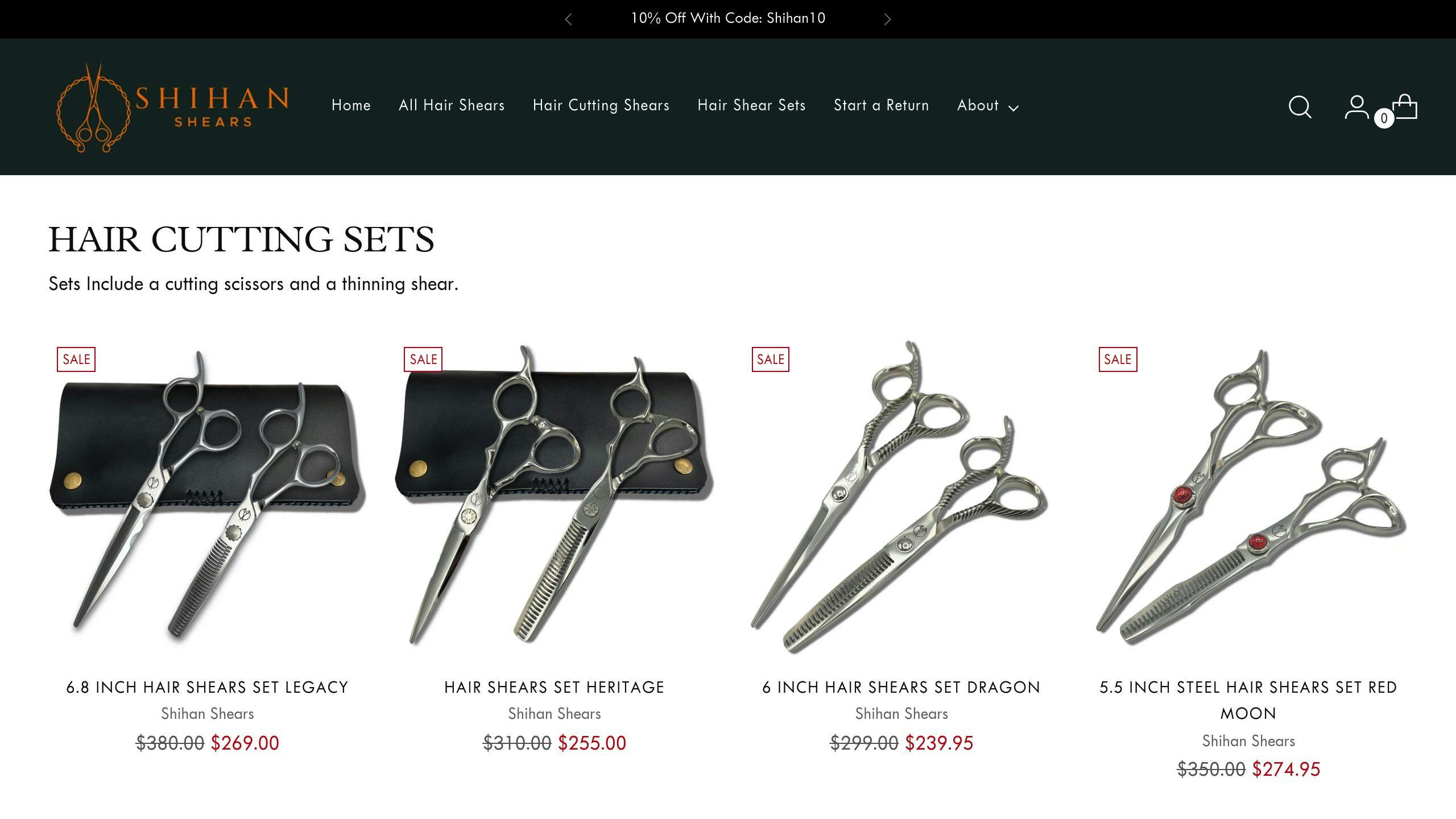

Shihan Shears and VG10 Steel Options

Shihan Shears offers VG10-crafted tools that balance precision and durability, making them a solid choice for professionals. Their shears stand out with:

| Feature | Advantage |

|---|---|

| Japanese Steel | Excellent edge retention and strength |

| Ergonomic Design | Less hand strain during long sessions |

| Lifetime Warranty | Added peace of mind for your purchase |

For those looking to benefit from VG10 steel, Shihan's shears are designed for precision and long-term use [3]. Their lifetime warranty adds extra assurance for high-volume stylists who need consistent performance.

Conclusion: Comparing VG10 and 440C Steel

Final Thoughts on VG10 vs. 440C

Choosing between VG10 and 440C steel comes down to understanding their strengths and how they align with your needs. Both materials have their own perks, catering to different professional demands.

| Characteristic | VG10 Steel | 440C Steel |

|---|---|---|

| Edge Retention | Excellent | Reliable |

| Initial Cost | Higher | Moderate |

| Maintenance Needs | Less frequent | Requires regular upkeep |

| Best Suited For | High-volume salons | Everyday use |

VG10 stands out for its sharper edges and durability, making it perfect for advanced cutting techniques and heavy daily use. On the other hand, 440C offers solid performance at a more budget-friendly price, making it a practical choice for those with standard needs.

For professionals like stylists and barbers, the decision hinges on how you prioritize performance versus cost. If long-term durability and precision are key, VG10 is the way to go. But if you're looking for a dependable option without breaking the bank, 440C is a strong contender. Think about your workload and techniques to make the best choice for your tools.

Why Top Hair Stylists Pay $2000 For Japanese Hair Shears

FAQs

Here are answers to some common questions about steel grades for professional shears to help you choose the right one.

What is the best grade of steel for shears?

For professional shears, steel with a hardness between 58-61 HRC is ideal. This range offers a good mix of sharpness, durability, and resistance to corrosion. Both VG10 and 440C steel surpass the 58 HRC mark, with VG10 reaching up to 61 HRC, making it excellent for maintaining a sharp edge over time.

Is 440C steel good for shears?

Yes, 440C steel is a reliable option for everyday salon use. With a hardness rating above 58 HRC, it delivers consistent performance in professional environments.

"440C delivers sharpness, durability, and daily reliability." [1]

This steel is a practical and budget-friendly choice, offering a balance of sharpness and durability. Deciding between VG10 and 440C depends on your specific requirements, as discussed earlier.